Nos solutions inspirent de nombreux secteurs dont certainement le vôtre

AVANTAGES

Pourquoi les micro-ondes ?

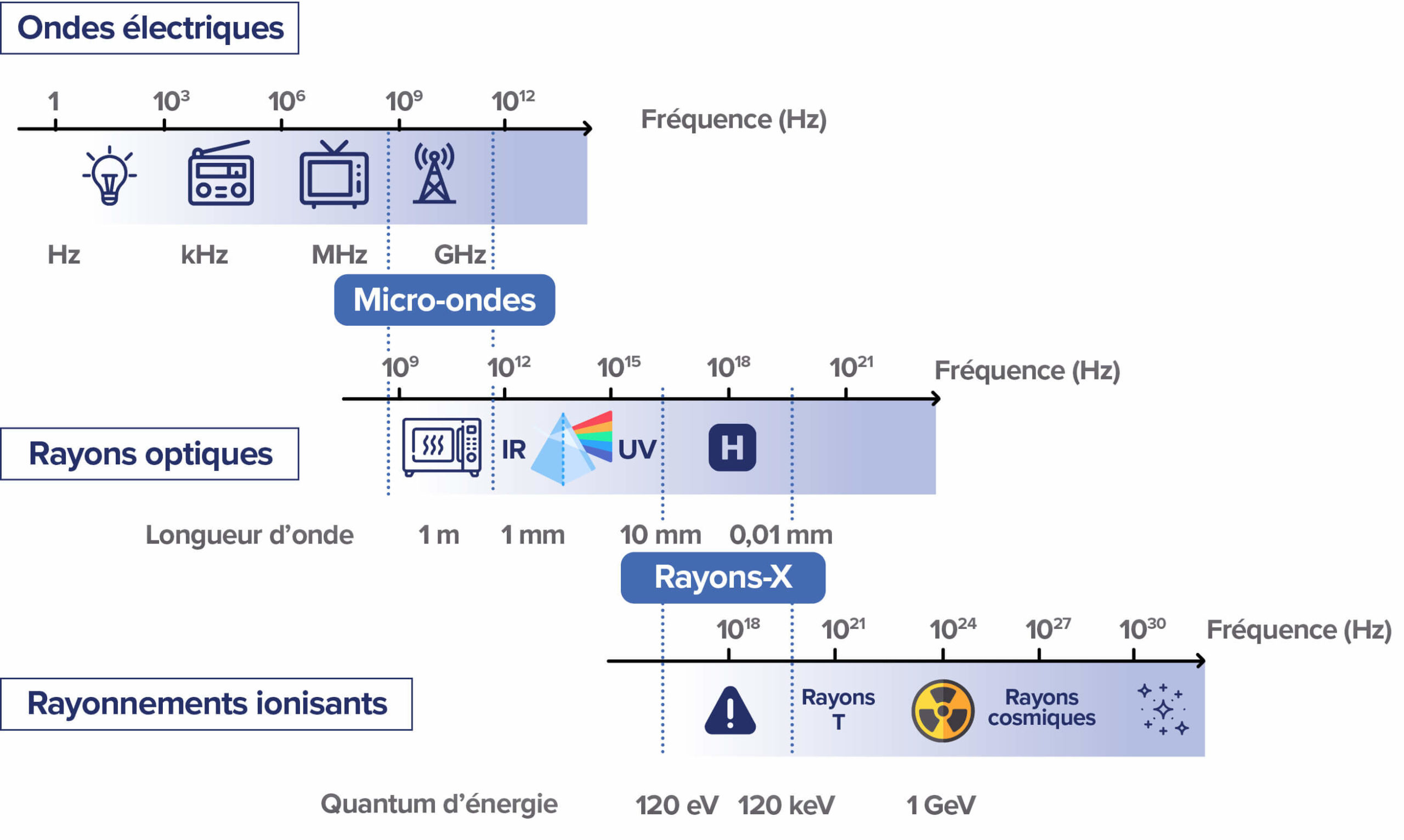

Qu’est ce que le rayonnement micro-ondes ?

Les micro-ondes sont des ondes électromagnétiques de longueur d’onde comprise entre l’infrarouge et les ondes de radiodiffusion soit environ entre 30 cm (1 GHz) et 1mm (300 GHz).

Réponse d’un matériau

au rayonnement micro-ondes

Lorsque le rayonnement micro-ondes rencontre un matériau, le matériau va absorber une partie de ce rayonnement et s’échauffer par dissipation du rayonnement micro-onde sous forme d’énergie calorifique. La partie du rayonnement non absorbée est réfléchie.

Certains matériaux

reflètent totalement

le rayonnement micro-ondes sans s’échauffer (matériau conducteur, métal)

Certains matériaux

sont transparents

au rayonnement micro-ondes et ne chauffent pas (quartz, téflon…)

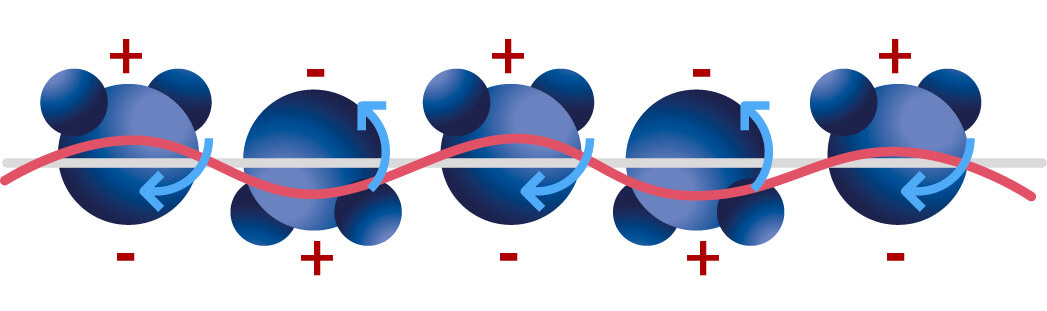

Certains matériaux se polarisent

(agitation moléculaire) et chauffent en présence du rayonnement micro-ondes (eau, plante, huile, solvant…)

Le comportement d’un matériau soumis à un rayonnement micro-ondes dépend de sa permittivité diélectrique ε

Plus la permittivité diélectrique est élevée, plus le matériau va amortir les micro-ondes et donc s’échauffer.

Le meilleur exemple est l’eau ε = 80

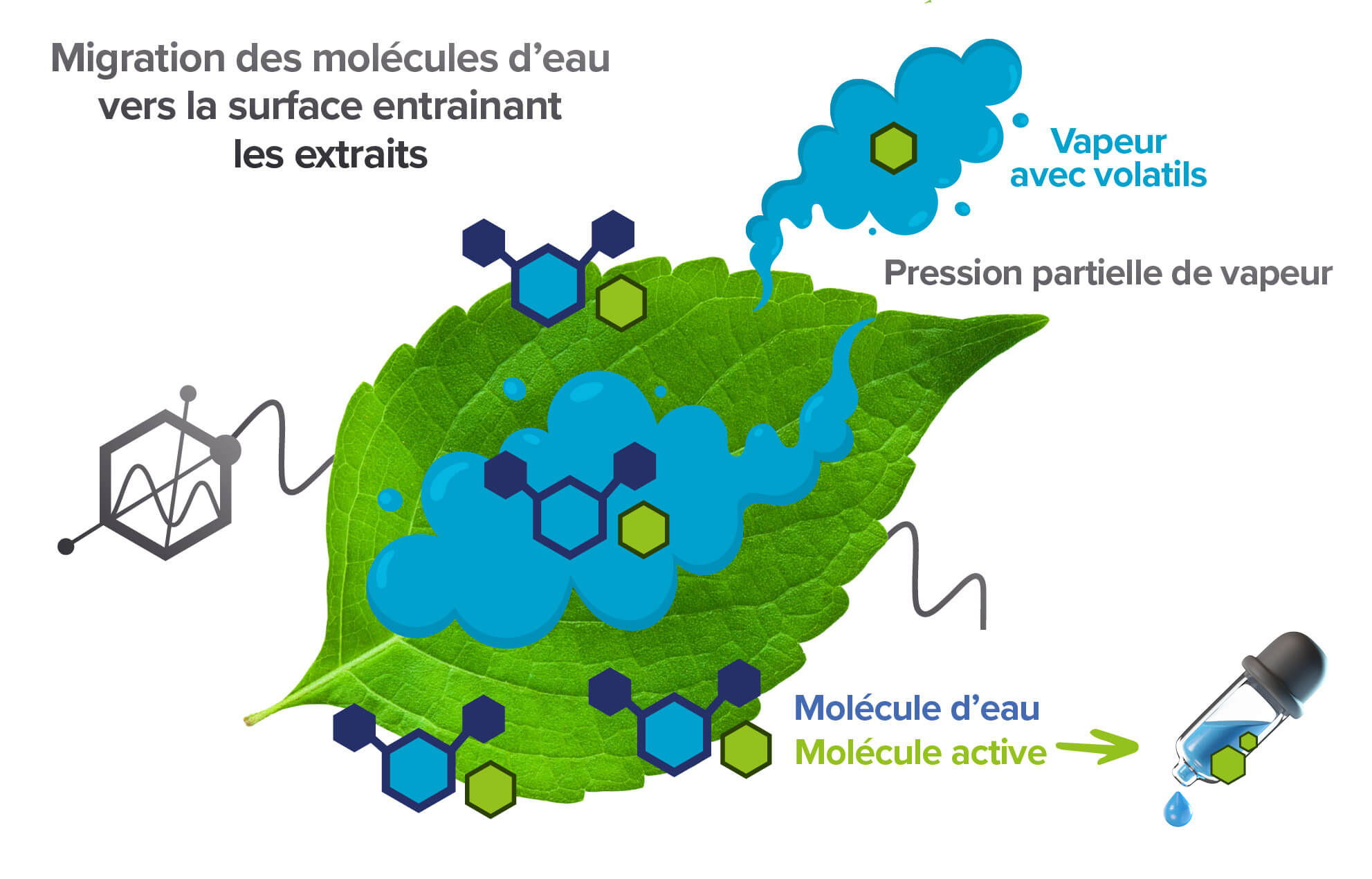

Cas de l’extraction végétale

Dans le cas d’une extraction végétale, les plantes fraîches (80 à 90% d’eau) ou réhydratées répondent très bien aux micro-ondes.

1. Vaporisation de certaines molécules d’eau à l’intérieur de la cellule de la plante

2. Augmentation de la pression partielle de vapeur

3. Effet mécanique « d’essorage »

4. Libération des principes actifs hors de la cellule de la plante

Avantages du procédé micro-ondes

Nos solutions vous permettent de gagner sur tous les tableaux !

Les avantages d’une chauffe par micro-ondes sont multiples :

Réduction

de 80 à 95%

des émissions de CO2

(divisée par 6,4)

Performance

Procédé classique →

Chauffe classique

de l’extérieur vers l’intérieur de la cellule

Procédé micro-ondes →

Chauffe sélective

de l’intérieur vers l’extérieur de la cellule

Gain de temps

15 – 30 min

contre plusieurs heures

pour un procédé traditionnel

Gain d’énergie

de 10 à 40%

par rapport au procédé traditionnel

Uniques équipements micro-ondes industriels

sur les marchés de l’extraction végétales, du minéral

et des hautes températures

Technologies uniques

pour des traitements homogènes

Procédés innovants associés

Extraction végétale : mixte micro-ondes et ultrasons, recyclage couche mince, recirculation à contre-courant.

Minéral : expansion d’argile,

dopants thermiques micro-ondes…

Machine spéciales adaptées au cahier des charges clients

Concentration élevée

des extraits recueillis → fort rendement

jusqu’à 98%

Procédés d’extraction répondant aux réglementations

Eco-Friendly et REACH

Haute qualité des extraits

Extraction sous azote, sous vide,

sous température contrôlée

Conservation des propriétés organoleptiques des actifs

possibilité de combiner les micro-ondes et les ultrasons afin d’augmenter le pouvoir d’extraction et d’accroître le nombre de molécules extraites

Disponibilité des équipements

en version ATEX

Modularité de l’équipement

Facilité d’installation et rapidité de mise en route

Economie circulaire

Modularité de l’équipement

Maintenance simplifiée

Nettoyage facile

Chauffe homogène par procédé de brassage breveté

équipements industriels disponibles en procédé par batch et en procédé en continu

Technologies et Procédés

protégés par brevets

– 15 BREVETS –

Offre globale incluant la valorisation des sous-produits

Possibilité de traiter différentes formes de plantes

(poudres, feuilles, broyats, branches)

Transposition

industrielle / scale up

Quelques kg à plusieurs T