Du laboratoire à l’unité industrielle

De l’idée aux réalisations

IDCO . Innovation Development COmpany

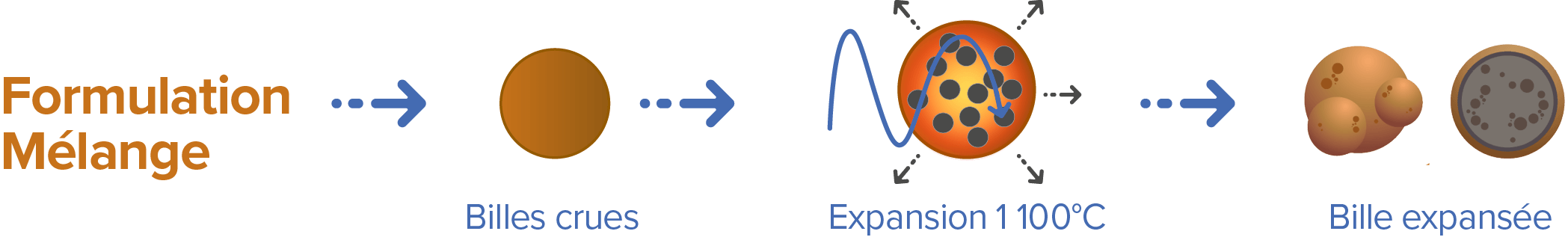

Société marseillaise, est née en 2000 sur la base d’une idée révolutionnaire et audacieuse : valoriser les boues de lavage de granulats de carrières en billes expansées par micro-ondes. C’est alors une application totalement innovante pour cette technologie.

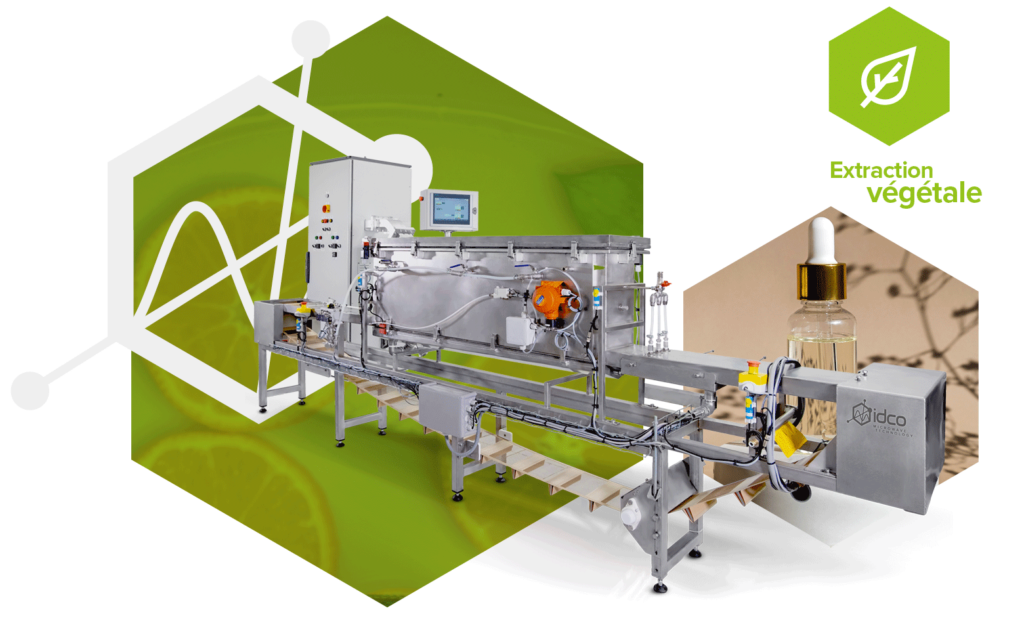

L’utilisation la technologie micro-onde dans de nouveaux domaines d’exploitation devient alors la raison d’être d’IDCO. Son implantation dans le Sud de la France, à proximité du parc naturel des calanques et proche de Grasse l’oriente naturellement vers l’extraction végétale.

Rapidement IDCO devient un ACTEUR MAJEUR dans 4 secteurs distincts :

Ces activités sont à l’origine de nombreux brevets, permettant de réduire les émissions de CO2, la consommation d’énergie, d’optimiser nos ressources naturelles et de développer l’économie circulaire…. Une réelle volonté d’engagement écologique et de participation active dans la préservation des ressources et la protection du climat !

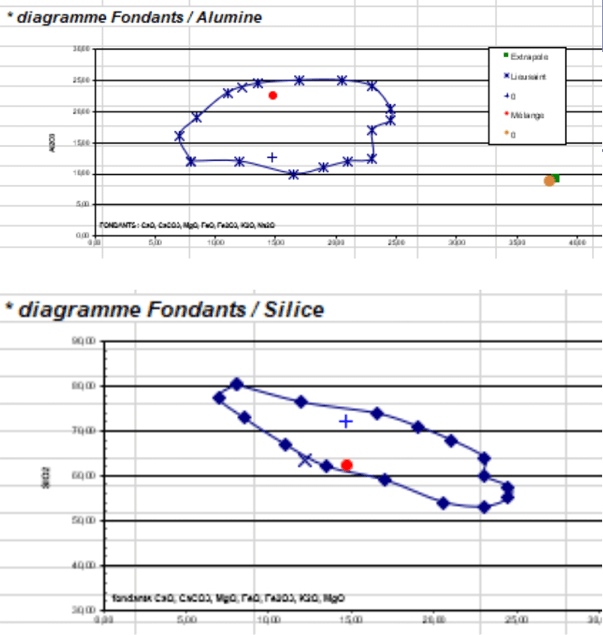

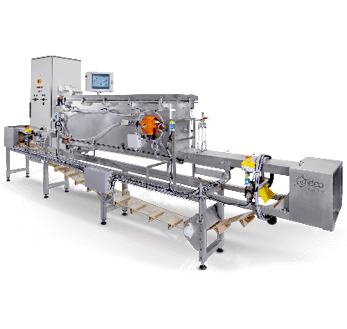

Aujourd’hui, IDCO conçoit, développe et commercialise des solutions industrielles complètes et innovantes basées sur la technologie micro-ondes permettant une haute efficacité et une chauffe homogène. La gamme d’équipements proposés permet des traitement par batch et en continu.

2021 marque une nouvelle étape dans l’échelle de nos équipements pour répondre aux besoins de l’industrie : nous développons des équipements de fortes puissances et une stratégie de licensing en partenariat avec nos clients et des intégrateurs.

IDCO est soutenu par

.

.

IDCO a été lauréat du 2e concours national de création d’entreprises de technologies innovantes et a obtenu le

1er prix du concours EDF Pulse Paca « Industrie du Futur » 2016

Historique

22 ans d’innovations et d’exclusivités mondiales

.2000

Naissance de la société ENTEMA – ENTreprise d’Expansion par Micro-ondes d’Argile pour valoriser les boues de carrières

Conception et développement d’une technologie micro-ondes à haute température à échelle industrielle

Réponse au problème d’homogénéité de chauffe des micro-ondes : solutions de brassage performantes

Brevets d’expansion d’argile par micro-ondes

.2003

Brevets de dispositif et procédé de traitement thermique avec brassage par micro-ondes

Obtention de granulés de verre par expansion

Mise en route d’un pilote industriel de traitement thermique haute température de matériaux granulaires par cuve rotative

(1100°C – 50 à 500 Kg/h – 80 KW – 915 MHz) (Istres-13)

Vitrification de REFIOM (Résidu d’Epuration des Fumées d’Incinération des Ordures Ménagères)

.2004

ENTEMA devient IDCO – Innovation Development COmpany

.2006

Obtention de granulés de verre de petit diamètre par expansion (impossible à obtenir par procédé industriel traditionnel)

.2007

Lancement de la plateforme d’essais de Marseille

.2010

Création d’un extracteur végétal continu à spires / d’un sécheur continu à spires – Gamme EXTRACTOR ECS

.2012

Lancement de l’activité « d’extraction végétale » et de la gamme

EXTRACTOR E

Conception et brevet de l’extracteur végétal par batch de laboratoire EXTRACTOR E200 – première mondiale : combinaison des technologies micro-ondes et ultrasons

Développement de la gamme CALCINATOR pour l’activité « minéral »

.2014

Lancement Commercial de l’EXTRACTOR E200

Brevet procédé « Recyclage solvant en couche mince » – première mondiale

Valorisation des boues calcaires en granulats légers

.2015

Développement de procédés de séchage mixte micro-ondes / air chaud

.2017

Lancement d’un extracteur végétale continu à tapis – Gamme EXTRACTOR ECT – première mondiale

.2018

Passage en supervision de l’ensemble des équipements

.2021

Développement d’un CALCINATOR continu rotatif CCR – Première mondiale

Lancement d’un extracteur végétal continu à spire ECS combinant les technologies micro-ondes et ultrasons en milieu liquide.

.2022

5 nouveaux brevets

Végétal

Plante à traiter

Choix du procédé

Définition du cahier des charges client

Extrait

Essais

Caractérisation des paramètres d’extraction (technologie, puissance micro-ondes, utilisation des ultrasons, temps de traitement, température…)

Valorisation des drèches

Dimensionnement

Unité industrielle

Analyse des résultats et des paramètres d’essais pour valider le dimensionnement de l’équipement industriel

Minéral

Cahier des charges

Définition du besoin client (produit , capacité, contraintes techniques, demandes spécifiques…)

Analyse et essais

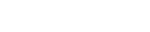

La connaissance de la composition chimique est indispensable pour évaluer la réponse micro-ondes, la faisabilité d’extraction, d’expansion ou de calcination et le besoin en solvant ou additifs

Logiciels expert

Unité industrielle

Analyse des résultats et des paramètres d’essais pour valider le dimensionnement de l’équipement industriel

Séchage

Cahier des charges

Définition du besoin client (produit, capacité, contraintes techniques , demandes spécifiques…). Teneur en eau du produit brut. Objectif de siccité finale

Analyse et essais

Essais sur E200 et ECT200, optimisation du brassage, teneurs en eau initiales et finales, débit et température air chaud, bilan énergétique

Logiciels expert

Détermination de la puissance micro-ondes, du débit et de la température d’air chaud.

Unité industrielle

Analyse des résultats et des paramètres d’essais pour valider le dimensionnement de l’équipement.

Traitement thermique

Cahier des charges

Définition du besoin client (produit, capacité, contraintes techniques, demandes spécifiques…).

Analyse chimique et granulométrique du produit brut. Température cible. Paliers. Permittivité diélectrique.

Analyse et essais

Essais sur C200 et C400, optimisation du brassage, perte au feu, bilan énergétique.

Paramètres de chauffe.

Logiciels expert

Détermination de la puissance micro-ondes, des températures et des paliers.

Unité industrielle

Analyse des résultats et des paramètres d’essais pour valider le dimensionnement de l’équipement.

Process

Des process basés sur la confiance et l’échange d’informations

Station d’essais – Marseille

Hall technique de 150 m2

Prestation : étude avec logiciels experts et essais

idco . solutions . industrielles . procédé micro-ondes .

Nos valeurs

Agir pour l’environnement et oeuvrer pour l’avenir sont nos valeurs fondatrices.

Les solutions IDCO permettent une meilleure efficacité industrielle tout en réduisant les émissions de C02, en économisant l’énergie, en préservant les ressources et en développant l’économie circulaire.

Faire mieux avec moins.

Plus que des avancées technologiques, IDCO propose une véritable révolution de process et de mode de réflexion.

idco . solutions . industrielles . procédé micro-ondes .

Équipe

idco . solutions . industrielles . procédé micro-ondes .

Témoignages

Chiffres clés

machines vendues

tonnes de CO2 évitées

kWh électrique économisés

de croissance

litres de solvant économisés